![]() SmCo Magnets Introduction

SmCo Magnets Introduction

01. SmCo (Samarium Cobalt) Magnets Profile

Samarium cobalt magnets can work under higher working temperature than neodymium. The cost of SmCo material is the most expensive, so SmCo magnets are recommended only when high temperature working environment is concerned.

SmCo permanent magnets characteristics:

1. SmCo permanent magnets have high magnetic energy product and high coercive force. The magnetic performance is much better than Alnico and ferrite permanent magnet. The Max. energy product is up to 239kJ/m3(30MGOe), which is three times of Alnico8 permanent magnet’s and eight times of ferrite permanent magnet’s (Y40), so the components made of SmCo material could be small, light and stable in property. It is widely applied to electro acoustic & telecommunication apparatus, electric motors, measure meters, peg-top, electronic watch, microwave apparatus, magnetic mechanism, sensor and other static or dynamic magnetic routes.

2. The curie temp. of SmCo permanent magnets is high and its temp. Coeff. is low. They are suitable for the application at 300℃ high temperature.

3. SmCo permanent magnets’ rigidity strength, tensile strength and pressure strength is low, so they are more fragile and easier to crack. The main ingredient of SmCo permanent magnets are metal cobalt(Co≥99.95%), so the price is higher.

4. SmCo magnets have good corrosion resistance performance, therefore generally the products do not need coating or plating.

02. SmCo (Samarium Cobalt) Magnets Production Process

Sintered SmCo magnets’s production process is same with sintered neodymium magnets but the parameters for the sintering temperature and time are different.

03. SmCo (Samarium Cobalt) Magnets Performance Datasheet

| Types | Material | Grade | Remanence (Br) T┃kGs | Coercive Force (Hcb) kA/m┃kOe | Intrinsic Coercivity (Hcj) kA/m┃kOe | Max. Energy Product ((BH)max) kJ/m³ ┃MGOe | Curie Temp. TC (℃) | Max. Working Temp. TW (℃) | Temp. Coefficient of Br T.C.α (Br) (%/°C) | Temp. Coefficient of Hcj T.C.β (Hcj) (%/°C) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1:5 SmCo | (SmPr)Co5 | YX16 | 0.81-0.85┃8.1-8.5 | 610-660┃7.8-8.3 | 1,194-1,830┃15-23 | 111-127┃14-16 | 750 | 250 | -0.05 | -0.3 |

| YX18 | 0.85-0.90┃8.5-9.0 | 650-700┃8.3-8.8 | 1,194-1,830┃15-23 | 127-143┃16-18 | 750 | 250 | -0.05 | -0.3 | ||

| YX20 | 0.90-0.94┃9.0-9.4 | 680-725┃8.5-9.1 | 1,194-1,830┃15-23 | 143-159┃18-20 | 750 | 250 | -0.05 | -0.3 | ||

| YX22 | 0.94-0.96┃9.4-9.6 | 710-750┃8.9-9.4 | 1,194-1,830┃15-23 | 159-175┃20-22 | 750 | 250 | -0.05 | -0.3 | ||

| YX24 | 0.96-1.00┃9.6-10.0 | 720-770┃9.2-9.7 | 1,194-1,830┃15-23 | 175-190┃22-24 | 750 | 250 | -0.05 | -0.3 | ||

| SmCo5 | YX16S | 0.79-0.84┃7.9-8.4 | 612-660┃7.7-8.3 | ≥1,830┃≥23 | 118-135┃15-17 | 750 | 250 | -0.035 | -0.28 | |

| YX18S | 0.84-0.90┃8.4-9.0 | 644-692┃8.1-8.7 | ≥1,830┃≥23 | 135-151┃17-19 | 750 | 250 | -0.04 | -0.28 | ||

| YX20S | 0.90-0.94┃9.0-9.4 | 684-732┃8.6-9.2 | ≥1,830┃≥23 | 151-167┃19-21 | 750 | 250 | -0.045 | -0.28 | ||

| YX22S | 0.92-0.96┃9.2-9.6 | 710-756┃8.9-9.5 | ≥1,830┃≥23 | 167-183┃21-23 | 750 | 250 | -0.045 | -0.28 | ||

| YX24S | 0.96-1.00┃9.6-10.0 | 740-788┃9.3-9.9 | ≥1,830┃≥23 | 183-199┃23-25 | 750 | 250 | -0.045 | -0.28 | ||

| (SmGd)Co5 (LTC) | LTC (YX-10) | 0.62-0.66┃6.2-6.6 | 485-517┃6.1-6.5 | ≥1,830┃≥23 | 75-88┃9.5-11 | 750 | 300 | Temp. Range | T.C.α (Br) | |

| 20-100°C | +0.0156 | |||||||||

| 100-200°C | +0.0087 | |||||||||

| 200-300°C | +0.0007 | |||||||||

| 2:17 SmCo | Sm2(CoFeCuZr)17 | YXG22H | 0.93-0.97┃9.3-9.7 | 676-740┃8.5-9.3 | ≥1,990┃≥25 | 160-175┃20-22 | 800 | 300 | -0.02 | -0.2 |

| YXG24H | 0.95-1.02┃9.5-10.2 | 700-750┃8.7-9.4 | ≥1,990┃≥25 | 175-191┃22-24 | 800 | 350 | -0.025 | -0.2 | ||

| YXG26H | 1.02-1.05┃10.2-10.5 | 750-780┃9.4-9.8 | ≥1,990┃≥25 | 191-207┃24-26 | 800 | 350 | -0.03 | -0.2 | ||

| YXG28H | 1.05-1.08┃10.5-10.8 | 756-796┃9.5-10 | ≥1,990┃≥25 | 207-220┃26-28 | 800 | 350 | -0.035 | -0.2 | ||

| YXG30H | 1.08-1.10┃10.8-11.0 | 788-835┃9.9-10.5 | ≥1,990┃≥25 | 220-240┃28-30 | 800 | 350 | -0.035 | -0.2 | ||

| YXG32H | 1.10-1.13┃11.0-11.3 | 812-860┃10.2-10.8 | ≥1,990┃≥25 | 230-255┃29-32 | 800 | 350 | -0.035 | -0.2 | ||

| YXG22 | 0.93-0.97┃9.3-9.7 | 676-740┃8.5-9.3 | ≥1,443┃≥18 | 160-175┃20-22 | 800 | 300 | -0.02 | -0.2 | ||

| YXG24 | 0.95-1.02┃9.5-1.02 | 692-764┃8.7-9.6 | ≥1,443┃≥18 | 175-191┃22-24 | 800 | 300 | -0.025 | -0.2 | ||

| YXG26 | 1.02-1.05┃10.2-10.5 | 748-796┃9.4-10.0 | ≥1,443┃≥18 | 191-207┃24-26 | 800 | 300 | -0.03 | -0.2 | ||

| YXG28 | 1.05-1.08┃10.5-10.8 | 756-812┃9.5-10.2 | ≥1,443┃≥18 | 207-220┃26-28 | 800 | 300 | -0.035 | -0.2 | ||

| YXG30 | 1.08-1.10┃10.8-11.0 | 788-835┃9.9-10.5 | ≥1,443┃≥18 | 220-240┃28-30 | 800 | 300 | -0.035 | -0.2 | ||

| YXG32 | 1.10-1.13┃11.0-11.3 | 812-860┃10.2-10.8 | ≥1,443┃≥18 | 230-255┃29-32 | 800 | 300 | -0.035 | -0.2 | ||

| YXG26M | 1.02-1.05┃10.2-10.5 | 676-780┃8.5-9.8 | 955-1,433┃44,913 | 191-207┃24-26 | 800 | 300 | -0.035 | -0.2 | ||

| YXG28M | 1.05-1.08┃10.5-10.8 | 676-796┃8.5-10.0 | 955-1,433┃44,913 | 207-220┃26-28 | 800 | 300 | -0.035 | -0.2 | ||

| YXG30M | 1.08-1.10┃10.8-11.0 | 676-835┃8.5-10.5 | 955-1,433┃44,913 | 220-240┃28-30 | 800 | 300 | -0.035 | -0.2 | ||

| YXG28L | 1.05-1.08┃10.5-10.8 | 541-764┃6.8-9.6 | 636-955┃44,785 | 207-220┃26-28 | 800 | 250 | -0.035 | -0.2 | ||

| YXG30L | 1.08-1.15┃10.8-11.5 | 541-796┃6.8-10.0 | 636-955┃44,785 | 220-240┃28-30 | 800 | 250 | -0.035 | -0.2 | ||

| (SmEr)2(CoTm)17 (LTC) | LTC (YXG22) | 0.94-0.98┃9.4-9.8 | 668-716┃8.4-9.0 | ≥1,443┃≥18 | 167-183┃21-23 | 840 | 300 | Temp. Range | T.C.α (Br) | |

| -50-25°C | +0.005 | |||||||||

| 20-100°C | -0.008 | |||||||||

| 100-200°C | -0.008 | |||||||||

| 200-300°C | -0.011 |

04. SI and CGS Unit Conversion for Magnetism Quantity

| Quantity | Symbol | SI Unit | CGS Unit | Unit Conversion |

| Remanence | Br | T | Gs | 1T=10kGs |

| Coercive Force | Hcb | kA/m | Oe | 1kA/m=4πOe≈12.57Oe |

| Intrinsic Coercivity | Hcj, iHc | kA/m | Oe | 1kA/m=4πOe≈12.57Oe |

| Max. Energy Product | BHmax | kJ/m3 | MGOe | 1kJ/m3=4π/102MGOe≈0.126MGOe |

| Magnetic Flux | Φ | Wb,Vs | Mx | 1Wb=1Vs=108Mx |

| Magnetization Intensity | M | T | Gs | 1T=10kGs |

| Magnetic Field Intensity | H | kA/m | Oe | 1kA/m=4πOe≈12.57Oe |

| Magnetic Induction Intensity | B | T | Gs | 1T=10kGs |

05. SmCo (Samarium Cobalt) Physical Properties

| Grade | SmCo5 (RECo5) | Sm2Co17 (RE2Co17) |

| Density | 8.2-8.4g/cm³ | 8.3-8.5g/cm³ |

| Curie Temperature | 750℃ | 800℃ |

| Max. Working Temp. | 250℃ | 300-350℃ |

| Temp. Coefficient of Br T.C.α (Br) | -0.05%/℃ | -0.03%/℃ |

| Temp. Coefficient of Hcj T.C.β (Hcj) | -0.3%/℃ | -0.2%/℃ |

| Recoil Permeability | 1.00-1.05 | 1.00-1.10 |

| Electrical Resistivity | 5~6×10-5Ω.cm | 8~9×10-5Ω.cm |

| Vickers Hardness | 450-500Hv | 500-600Hv |

| Thermal Conductivity | 12 | |

| Thermal Expansion Coefficient (Perpendicular to Magnetization Direction) | 13×10-6/℃ | 11×10-6/℃ |

| Thermal Expansion Coefficient (Parallel to Magnetization Direction) | 6×10-6/℃ | 8×10-6/℃ |

| Compressive Strength | 420~680 Mpa | 700~830 MPa |

06. Physical Properties Comparison (Sm2Co17 Vs NdFeB)

| Material | Sm2Co17 | NdFeB |

|---|---|---|

| Remanence (Br) | (0.82-1.16)T | (1.1-1.5)T |

| Intrinsic Coercivity (Hcj) | (493~1,990)MA/m | (875~2,790)MA/m |

| Recoil Permeability | 1.05 | 1.05 |

| Temp. Coefficient of Br (T.C.α (Br)) | ≈-0.03%/℃ | (-0.12 ~ -0.10)%/℃ |

| Temp. Coefficient of Hcj (T.C.β (Hcj)) | ≈-0.2%/℃ | ≈-0.6%/℃ |

| Curie Temperature | 800℃ | (310-370)℃ |

| Density | (8.2~8.4)g/cm³ | (7.3~7.5)g/cm³ |

| CTE (Parallel to Magnetization Direction) | 8×10-6%/K | 6.5×10-6%/K |

| Flexural Strength | ≈150N/mm² | ≈250N/mm² |

| Compressive Strength | ≈800N/mm² | ≈1,100N/mm² |

| Tensile Strength | ≈35N/mm² | ≈75N/mm² |

| Vickers Hardness | 500-600Hv | 550-650Hv |

| Electrical Resistivity | (8.0~9.0)×10-5 Ω.cm | (11-17)x10-5 Ω.cm |

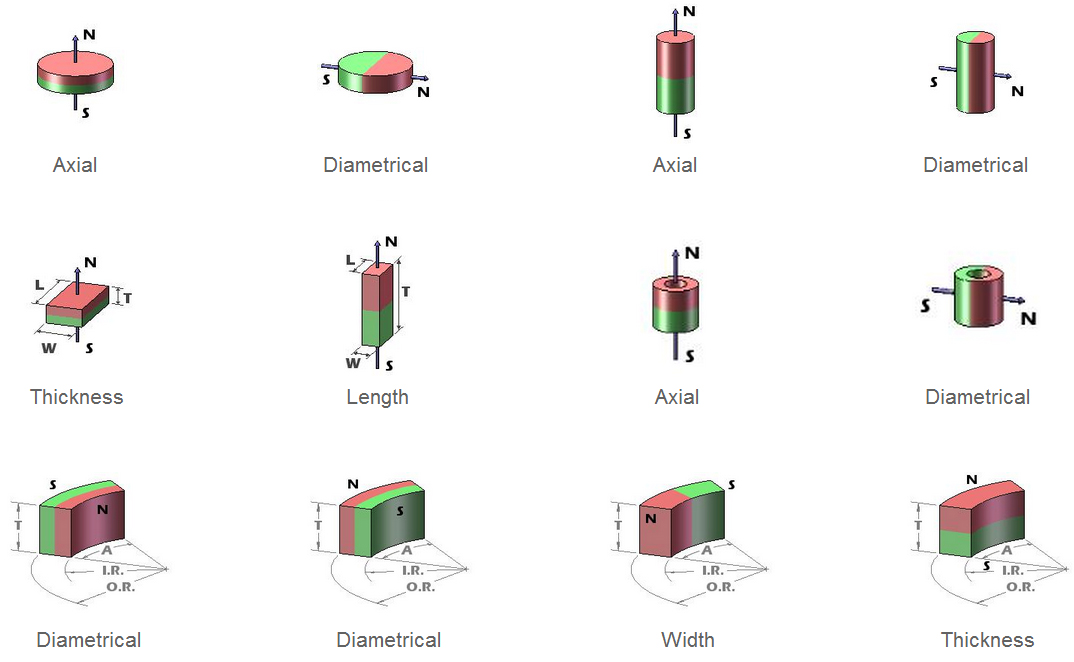

07. SmCo (Samarium Cobalt) Magnets Magnetization Directions

08. Permanent Magnets Comparison

| Permanent Magnets | (BH)max (MGOe) | Curie Temperature (°C) | Max. Working Temp. (℃) | Anti-corrosion | Machinability |

|---|---|---|---|---|---|

| Sintered NdFeB Magnets | 27-52 | 310-370 | 80-230 | Bad | Normal |

| AlNiCo Magnets | 1.1-11.5 | 890 | 500 | Good | Fair |

| SmCo5 | 14-25 | 750 | 250 | Good | Normal |

| Sm2Co17 | 22-32 | 800-840 | 350 | Good | Normal |

| Ferrite Magnets | 0.8-5.3 | 450 | 250 | Good | Normal |

| Bonded NdFeB Magnets | 3-12 | 350 | 160 | Good | Good |

09. SmCo Magnets Shipping Methods

(TNT, DHL, FedEx, UPS, etc), Air, Sea.

a: If the weight is under 40kgs, we recommend to send it in shielding boxes by Express.

b: If the weight is between 40-100kgs, it can be sent by Express or Air.

c: If the weight is over 100kgs, we recommend to ship them by Sea.

10. Typical Shapes of SmCo Magnets

For more details about SmCo magnets, please send message to us or email to sales@sinnyuan.com. We will reply to you as early as possible.