Ferrite (ceramic) magnets shapes

Ferrite (ceramic) magnets can be disc, ring, cylinder, block, arc, tile shaped for the applications on sensors, motors, rotors, wind turbines, loudspeakers, etc.

FOB Price: US $0.1 – 10 / Piece | Get Latest Price

Min.Order Quantity: 100 Piece

Supply Ability: 5,000,000 Piece/Month

Port: Shanghai/Hangzhou/Ningbo

Payment Terms: T/T, Western Union, Paypal

Delivery Time: About 7-25 days

Quick Details

| Place of Origin: Zhejiang, China (Mainland) | Brand Name: Sinnyuan magnets |

| Product Name: Ferrite/Ceramic magnets | Type: Permanent magnets |

| Composite: Ferrite magnets | Shape: Block, tile, arc, disc, ring, customized |

| Material: Ferrite magnets | Grade: Shown in the grade chart below |

| Size: Customized | Accuracy: 0.1mm |

| Magnetization Direction: Customzied specific requirements | Application: Industrial magnets |

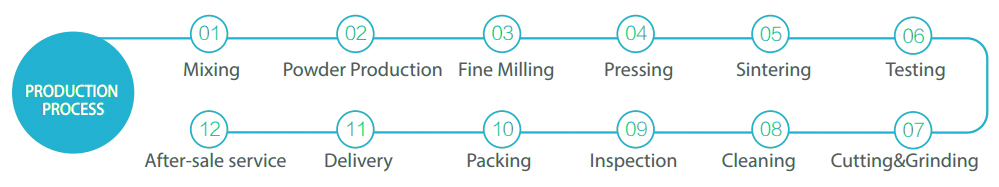

Ferrite (Ceramic) Magnets Production Process

Ferrite (ceramic) Magnets Material Grades

Mostly Used national standard – SJ285-77 permanent ferrite magnet standard

| Grade | Br | Hcb(BHC) | Hcj(IHC) | (BH)max | ||||

| MT | KG | KA/m | Koe | KA/m | KOe | Kj/m3 | MGOe | |

| Y10T(=C1) | 200/218 | 2.00/2.18 | 125/145 | 1.57/1.82 | 210/250 | 2.64/3.14 | 6.5/8.0 | 0.8/1.0 |

| Y25 | 360/370 | 3.60/3.70 | 135/150 | 1.70/1.88 | 140/170 | 1.76/2.14 | 22.5/25.3 | 2.8/3.2 |

| Y30(=C5) | 380/385 | 3.80/3.85 | 191/210 | 2.40/2.64 | 199/220 | 2.50/2.51 | 26.0/28 | 3.4/3.7 |

| Y30BH | 380/390 | 3.80/3.90 | 223/235 | 2.80/2.95 | 231/245 | 2.90/3.08 | 27.0/30.0 | 3.4/3.7 |

| Y33 | 410/420 | 4.10/4.20 | 220/235 | 2.77/2.95 | 225/240 | 2.83/3.01 | 31.5/33.0 | 4.0/4.2 |

| Y35 | 400/410 | 4.00/4.10 | 175/195 | 2.20/2.45 | 180/200 | 2.26/2.51 | 30.0/32.0 | 3.8/4.0 |

| C8(=C8A) | 385/390 | 3.85/3.90 | 235/255 | 2.95/3.20 | 242/265 | 3.05/3.33 | 27.8/30.0 | 3.5/3.7 |

| C10 | 400/410 | 4.00/4.10 | 288/300 | 3.62/3.77 | 280/287 | 3.51/3.60 | 30.4/31.9 | 3.8/4.0 |

Ferrite (Ceramic) Magnets Chinese Standard (SJ/T10410 2002)

| Grade | Remanence Br | Coercive Force Hcb | Intrinsic Coercivity Hcj | Max. Energy Product (BH)max | ||||

| mT | Gs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | |

| Y8T | 200-235 | 2,000-2,350 | 125-160 | 1.57-2.01 | 210-280 | 2.64-3.52 | 6.5-9.5 | 0.8-1.2 |

| Y22H | 310-360 | 3,100-3,600 | 220-250 | 2.76-3.14 | 280-320 | 3.52-4.02 | 20.0-24.0 | 2.5-3.0 |

| Y25 | 360-400 | 3,600-4,000 | 135-170 | 1.70-2.14 | 140-200 | 1.76-2.51 | 22.5-28.0 | 2.8-3.5 |

| Y26H-1 | 360-390 | 3,600-3,900 | 220-250 | 2.76-3.14 | 225-255 | 2.83-3.20 | 23.0-28.0 | 2.9-3.5 |

| Y26H-2 | 360-380 | 3,600-3,800 | 263-288 | 3.30-3.62 | 318-350 | 3.99-4.40 | 24.0-28.0 | 30-3.5 |

| Y27H | 350-380 | 3,500-3,800 | 225-240 | 2.83-3.01 | 235-260 | 2.95-3.27 | 25.0-29.0 | 3.1-3.6 |

| Y28 | 370-400 | 3,700-4,000 | 175-210 | 2.20-2.64 | 180-220 | 2.26-2.76 | 26.0-30.0 | 3.3-3.8 |

| Y28H-1 | 380-400 | 3,800-4,000 | 240-260 | 3.01-3.27 | 250-280 | 3.14-3.52 | 27.0-30.0 | 3.4-3.8 |

| Y28H-2 | 360-380 | 3,600-3,800 | 271-295 | 3.40-3.71 | 382-405 | 4.80-5.09 | 26.0-30.0 | 3.3-3.8 |

| Y30H-1 | 380-400 | 3,800-4,000 | 230-275 | 2.89-3.45 | 235-290 | 2.95-3.64 | 27.0-32.5 | 3.4-4.1 |

| Y30H-2 | 395-415 | 3,950-4,150 | 275-300 | 3.45-3.77 | 310-335 | 3.89-4.21 | 27.0-32.0 | 3.4-4.0 |

| Y32 | 400-420 | 4,000-4,200 | 160-190 | 2.01-2.39 | 165-195 | 2.07-2.45 | 30.0-33.5 | 3.8-4.2 |

| Y32H-1 | 400-420 | 4,000-4,200 | 190-230 | 2.39-2.89 | 230-250 | 2.89-3.14 | 31.5-35.0 | 4.0-4.4 |

| Y32H-2 | 400-440 | 4,000-4,400 | 224-240 | 2.81-3.01 | 230-250 | 2.89-3.14 | 31.0-34.0 | 3.9-4.3 |

| Y33 | 410-430 | 4,100-4,300 | 220~250 | 2.76-3.14 | 225-255 | 2.83-3.20 | 31.5-35.0 | 4.0-4.4 |

| Y33H | 410-430 | 4,100-4,300 | 250-270 | 3.14-3.39 | 250-275 | 3.14-3.45 | 31.5-35.0 | 4.0-4.4 |

| Y34 | 420-440 | 4,200-4,400 | 200-230 | 2.51-2.89 | 205-235 | 2.57-2.95 | 32.5-36.0 | 4.1-4.5 |

| Y35 | 430-450 | 4,300-4,500 | 215-239 | 2.70-3.00 | 217-242 | 2.73-3.04 | 33.1-38.2 | 4.2-4.8 |

| Y36 | 430-450 | 4,300-4,500 | 247-271 | 3.10-3.40 | 250-274 | 3.14-3.44 | 35.1-38.3 | 4.4-4.8 |

| Y38 | 440-460 | 4,400-4,600 | 285-305 | 3.58-3.83 | 294-310 | 3.69-3.89 | 36.6-40.6 | 4.6-5.1 |

| Y40 | 440-460 | 4,400-4,600 | 330-354 | 4.14-4.45 | 340-360 | 4.27-4.52 | 37.6-41.8 | 4.7-5.3 |

Ferrite (Ceramic) Magnets USA Standard

| Grade | Remanence Br | Coercive Force Hcb | Intrinsic Coercivity Hcj | Max. Energy Product (BH)max | ||||

| mT | kGs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | |

| C1 | 230 | 2.30 | 148 | 1.86 | 258 | 3.50 | 8.36 | 1.05 |

| C5 | 380 | 3.80 | 191 | 2.40 | 199 | 2.50 | 27.00 | 3.40 |

| C7 | 340 | 3.40 | 258 | 3.23 | 318 | 4.00 | 21.90 | 2.75 |

| C8/C8A | 385 | 3.85 | 235 | 2.95 | 242 | 3.05 | 27.80 | 3.50 |

| C8B | 420 | 4.20 | 232 | 2.91 | 236 | 2.96 | 32.80 | 4.12 |

| C9 | 380 | 3.80 | 280 | 3.52 | 320 | 4.01 | 26.40 | 3.32 |

| C10 | 400 | 4.00 | 280 | 3.52 | 284 | 3.57 | 30.40 | 3.82 |

| C11 | 430 | 4.30 | 200 | 2.51 | 204 | 2.56 | 34.40 | 4.32 |

| C12 | 400 | 4.00 | 290 | 3.65 | 318 | 4.00 | 32.00 | 4.00 |

Ferrite (Ceramic) Magnets Japan TDK standard

| Grade | Composition | Remanence Br | Coercive Force Hcb | Intrinsic Coercivity Hcj | Max. Energy Product (BH)max | ||||

| mT | kG | kA/m | kOe | kA/m | kOe | KJ/m3 | MGOe | ||

| FB40 | SrO6Fe2O3 | 410+/-10 | 4.1+/-10 | 234.8+/-11.9 | 2.95+/-0.15 | 238.7+/-15.9 | 3.0+/-0.2 | 31.4+/-1.6 | 3.95+/-0.2 |

| FB3N | SrO6Fe2O3 | 395+/-15 | 3.95+/-15 | 234.8+/-11.9 | 2.95+/-0.15 | 238.7+/-15.9 | 3.0+/-0.2 | 28.7+/-2.4 | 3.6+/-0.3 |

| FB3G | SrO6Fe2O3 | 375+/-15 | 3.75+/-15 | 254.6+/-15.9 | 3.2+/-0.2 | 270.6+/-19.9 | 3.4+/-0.25 | 25.9+/-2.4 | 3.25+/-0.3 |

| FB3X | SrO6Fe2O3 | 375+/-15 | 3.75+/-15 | 234.8+/-11.9 | 2.95+/-0.15 | 238.7+/-15.9 | 3.0+/-0.2 | 25.9+/-2.4 | 3.25+/-0.3 |

| FB1A | SrO6Fe2O3 | 220+/-15 | 2.20+/-15 | 159.2+/-15.9 | 2.0+/-0.2 | 258.6+/-19.9 | 3.25+/-0.25 | 8.9+/-1.6 | 1.1+/-0.2 |

| FB5H | SrO6Fe2O3 | 405+/-15 | 4.05+/-15 | 298.4+/-11.9 | 3.75+/-0.15 | 322.3+/-11.9 | 4.05+/-0.15 | 31.1+/-1.6 | 3.9+/-0.2 |

| FB4X | SrO6Fe2O3 | 420+/-10 | 4.20+/-10 | 234.8+/-11.9 | 2.95+/-0.15 | 238.7+/-15.9 | 3.0+/-0.2 | 33.4+/-1.6 | 4.2+/-0.2 |

| FB4B | SrO6Fe2O3 | 400+/-10 | 4.00+/-10 | 254.6+/-11.9 | 3.2+/-0.2 | 262.6+/-19.9 | 3.3+/-0.25 | 30.3+/-1.6 | 3.8+/-0.2 |

| FB4A | SrO/BaO6Fe2O3 | 410+/-10 | 4.10+/-10 | 175.1+/-15.9 | 2.2+/-0.2 | 176.7+/-15.9 | 2.22+/-0.2 | 31.8+/-1.6 | 4.0+/-0.2 |

| FBGN | SrO6Fe2O3 | 440+/-10 | 4.40+/-10 | 258.6+/-11.9 | 3.25+/-0.15 | 262.6+/-11.9 | 3.3+/-0.15 | 36.7+/-1.6 | 4.6+/-0.2 |

| FB6B | SrO6Fe2O3 | 420+/-10 | 4.20+/-10 | 302.4+/-11.9 | 3.8+/-0.15 | 318.3+/-11.9 | 4.0+/-0.15 | 33.4+/-1.6 | 4.2+/-0.2 |

| FB6H | SrO6Fe2O3 | 400+/-10 | 4.00+/-10 | 302.4+/-11.9 | 3.8+/-0.15 | 358.1+/-11.9 | 4.5+/-0.15 | 30.3+/-1.6 | 3.8+/-0.2 |

| FB6E | SrO6Fe2O3 | 380+/-10 | 3.80+/-10 | 290.5+/-11.9 | 3.65+/-0.15 | 393.9+/-11.9 | 4.95+/-0.15 | 27.5+/-1.6 | 3.45+/-0.2 |

| FB5N | SrO6Fe2O3 | 440+/-10 | 4.40+/-10 | 256.8+/-11.9 | 2.85+/-0.15 | 2259.2+/-11.9 | 2.88+/-0.15 | 36.7+/-1.6 | 4.6+/-0.2 |

| FB5B | SrO6Fe2O3 | 420+/-10 | 4.20+/-10 | 262.6+/-11.9 | 3.3+/-0.15 | 266.6+/-11.9 | 3.35+/-0.15 | 33.4+/-1.6 | 4.2+/-0.2 |

Ferrite (Ceramic) Magnets IEC Standard (IEC 60404-8-1)

| Grade | Remanence Br | Coercive Force Hcb(Hc) | Intrinsic Coercivity Hcj(Hci) | Max. Energy Product (BH)max | ||||

| mT | kGs | kA/m | kOe | kA/m | kOe | KJ/m³ | MGOe | |

| HF8/22 | 200/220 | 2.00/2.20 | 125/140 | 1.57/1.76 | 220/230 | 2.76/2.89 | 6.5/6.8 | 0.8/1.1 |

| HF20/19 | 320/333 | 3.20/3.33 | 170/190 | 2.14/2.39 | 190/200 | 2.39/2.51 | 20.0/21.0 | 2.5/2.7 |

| HF20/28 | 310/325 | 3.10/3.25 | 220/230 | 2.76/2.89 | 280/290 | 3.52/3.64 | 20.0/21.0 | 2.5/2.7 |

| HF22/30 | 350/365 | 3.50/3.65 | 255/265 | 3.20/3.33 | 290/300 | 3.64/3.77 | 22.0/23.5 | 2.8/3.0 |

| HF24/16 | 350/365 | 3.50/3.65 | 155/175 | 1.95/2.20 | 160/180 | 2.01/2.26 | 24.0/25.5 | 3.0/3.2 |

| HF24/23 | 350/365 | 3.50/3.65 | 220/230 | 2.76/2.89 | 230/240 | 2.89/3.01 | 24.0/25.5 | 3.0/3.2 |

| HF24/35 | 360/370 | 3.60/3.70 | 260/270 | 3.27/3.39 | 350/360 | 4.40/4.52 | 24.0/25.5 | 3.0/3.2 |

| HF26/16 | 370/380 | 3.70/3.80 | 155/175 | 1.95/2.20 | 160/180 | 2.01/2.26 | 26.0/27.0 | 3.2/3.4 |

| HF26/18 | 370/380 | 3.70/3.80 | 175/190 | 2.20/2.39 | 180/190 | 2.26/2.39 | 26.0/27.0 | 3.3/3.4 |

| HF26/24 | 370/380 | 3.70/3.80 | 230/240 | 2.89/3.01 | 240/250 | 3.01/3.14 | 26.0/27.0 | 3.3/3.4 |

| HF26/26 | 370/380 | 3.70/3.80 | 230/240 | 2.89/3.01 | 260/270 | 3.27/3.39 | 26.0/27.0 | 3.3/3.4 |

| HF26/30 | 385/395 | 3.85/3.95 | 260/270 | 3.27/3.39 | 300/310 | 3.77/3.89 | 26.0/27.0 | 3.3/3.4 |

| HF28/26 | 385/395 | 3.85/3.95 | 250/265 | 3.14/3.33 | 260/275 | 3.27/3.45 | 28.0/30.0 | 3.5/3.8 |

| HF28/28 | 385/395 | 3.85/3.95 | 260/270 | 3.27/3.39 | 280/290 | 3.50/3.60 | 28.0/30.0 | 3.5/3.8 |

| HF30/26 | 395/405 | 3.95/4.05 | 250/260 | 3.14/3.33 | 260/270 | 3.27/3.39 | 30.0/31.5 | 3.8/3.9 |

| HF32/17 | 410/420 | 4.10/4.20 | 160/180 | 2.01/2.26 | 165/175 | 2.07/2.20 | 32.0/33.0 | 4.0/4.1 |

| HF32/22 | 410/420 | 4.10/4.20 | 215/225 | 2.70/2.83 | 220/230 | 2.76/2.89 | 32.0/33.0 | 4.0/4.1 |

| HF32/25 | 410/420 | 4.10/4.20 | 240/250 | 3.01/3.14 | 250/260 | 3.14/3.27 | 32.0/33.0 | 4.0/4.1 |

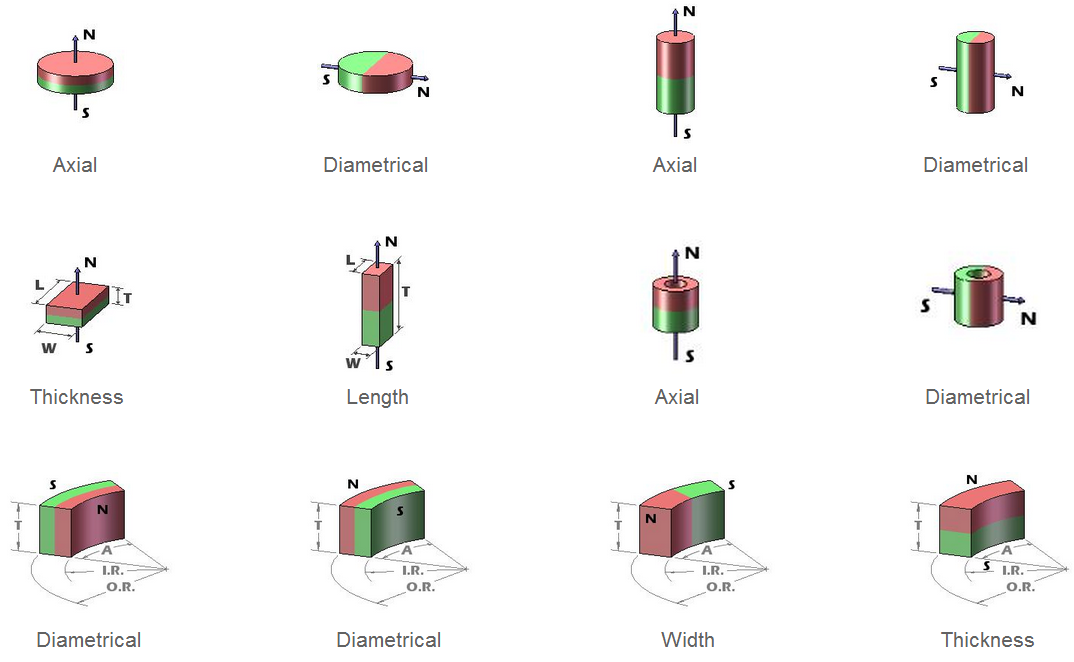

Ferrite (ceramic) Magnets Magnetization Directions

Physical Properties of Ferrite Magnets

| Curie Temperature (°C) | 450 |

| Maximum Operating Temperature (°C) | 250 |

| Hardness (Hv) | 480-580 |

| Density (g/cm3) | 4.8 - 4.9 |

| Relative Recoil Permeability (μrec) | 1.05 - 1.20 |

| Saturation Field Strength, kOe (kA/m) | 10 (800) |

| Temperature Coefficient of Br (%/°C) | -0.2 |

| Temperature Coefficient of iHc (%/°C) | 0.3 |

| Tensile Strength (N/mm) | <100 |

| Transverse Rupture Strength (N/mm) | 300 |

Ferrite (ceramic) Magnets Shipping Methods

(TNT, DHL, FedEx, UPS, etc), Air, Sea.

a: If the weight is under 40kgs, we recommend to send it in shielding boxes by Express.

b: If the weight is between 40-100kgs, it can be sent by Express or Air.

c: If the weight is over 100kgs, we recommend to ship them by Sea.

For more details about ferrite (ceramic) magnets shaped as a block, ring, tile or disk, please send message to us or email to sales@sinnyuan.com. We will reply to you as early as possible.