Cone neodymium magnets

Cone neodymium magnets are perfectly suitable for whiteboards, magnetic boards or other metal surfaces. The small end holds the paper securely and it can be easily removed by turning it sideways.

FOB Price: US $0.01 – 10 / Piece | Get Latest Price

Min.Order Quantity: 100 Piece

Supply Ability: 5,000,000 Piece/Month

Port: Shanghai/Hangzhou/Ningbo

Payment Terms: T/T, Western Union, Paypal

Delivery Time: About 7-25 days

Relative Products

Quick Details

Some of Cone Neodymium Magnets Sizes We Are Making

- With Inch Dimensions

- With Metric Dimensions

SI and CGS Unit Conversion for Magnetism Quantity

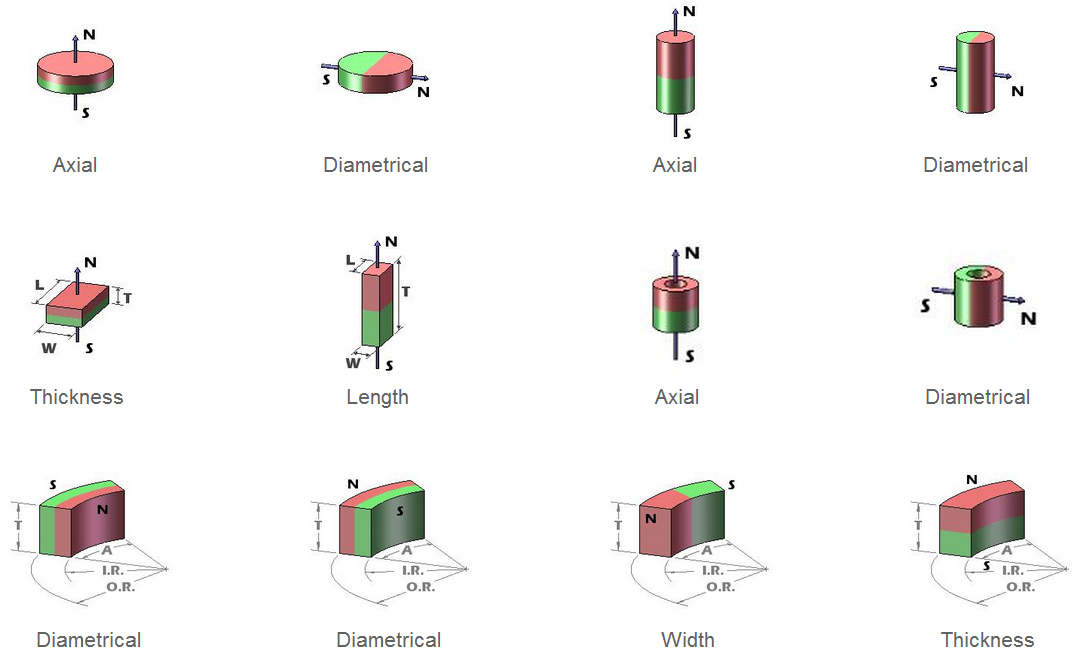

Neodymium Magnets Magnetization Directions

Neodymium Magnets Surface Treatment (Plating & Coating)

Neodymium Magnets Packaging

– Inner packaging

– Standard Air and Express Packaging

– Standard Sea Packaging

Neodymium Magnets Shipping Methods

(TNT, DHL, FedEx, UPS, etc), Air, Sea.

a: If the weight is under 40kgs, we recommend to send it in shielding boxes by Express.

b: If the weight is between 40-100kgs, it can be sent by Express or Air.

c: If the weight is over 100kgs, we recommend to ship them by Sea.

Typical Shapes of Neodymium Magnets

For more details about cone neodymium magnets, please send message to us or email to sales@sinnyuan.com. We will reply to you as early as possible.